Showroom

You will get a wide range of premium quality Container Liners in our company. These are used for safe as well as clean packaging as these are highly durable, tear proof, high performance efficient, easy to use and maintain.

We are providing a variety of standard quality FIBC Bag which is utilized for packaging products in bulk. It is light in weight, high in strength, tear proof, high performance efficient and more.

The offered superior quality Jumbo Bags are known for their sturdy structure, high strength, spacious nature and so on. These are used to transport goods in bulk due to their tear proof as well as light weight body.

Bulk bags are jumbo sized bags that can be used in industries for storing and transporting free-flowing to granular material. Different material, from flour to cereals to sand can be transported in such bags.

Baffle bags are four panel bags that can be used for storage and transportation of agro products to pharmaceutical products. The square shaped bags maintain their shape in order to maintain their stability when completely filled.

Plastic woven jumbo bags can be used to transport dry, powdered as well as granular material. The material packed in these bags will be protected from contamination.

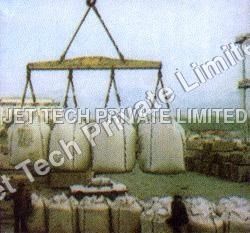

Basket slings are used during transportation and handling of load. Theuse of material handling slings is easy. Bagged cargo can be lifted and moved by the high strength slings.

Transport all dry material in bulk stored in these container bags. Whether you produce or deal in fertilizers, minerals, or agro products, you will always need such bags for bulk storage and transportation of material.

FIBC Storage Bags offer optimum flexibility, easy portability, and a fine finish. Their tear-resistant design ensures durability. Advantages include efficient material handling, secure storage, and convenient transportation. Widely used in various industries, these bags streamline processes and provide a reliable solution for storing and transporting bulk materials with ease.

We are dealing only in New and Fresh Bags. We DO NOT deal in any used bag.